The ZRPF series silver micro powder has the characteristics of low packing density, high oil absorption, and good conductivity. It is mainly used as the main filler for low silver content low-temperature curing electronic pastes, such as thin film switches, carbon film potentiometers, silver pastes, etc.

+86-18988684013

+86-18988684013Powder growth mechanism, component segregation, particle size and distribution, microstructure control, aggregation, surface state and purity control methods, etc.

High temperature reaction process, process thermodynamics, and kinetic laws.

Multi component combination relationship, homogeneous mixing, crushing, dispersibility, surface additive combination, stability and adaptability control.

Process energy efficiency management and lean production management.

| Model | ZRPF-01 | ZRPF-02 | ZRPF-03 | ZRPF-03 |

| Application Areas | Low silver content low temperature curing paste | |||

| Average particle size (μm) | 6.0-8.0 | 7.0-9.0 | 8.0-10.0 | 5.0-8.0 |

| Bulk density (g/cm³ ) | 0.60-0.80 | 0.80-1.00 | 0.60-0.90 | 1.00-2.00 |

| Tap density (g/cm³ ) | 1.50-2.00 | 1.50-2.00 | 1.50-2.00 | 2.00-2.50 |

| Specific surface area (m²/g) | 1.80-3.20 | 1.80-3.20 | 1.80-3.20 | 1.80-3.20 |

| Morphology | High conductivity | Anti-oxidation | High conductivity | Flocculent powder |

|

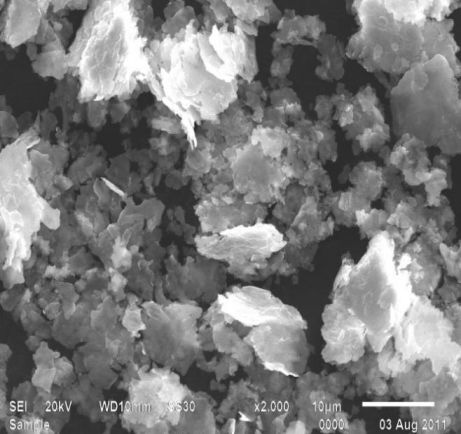

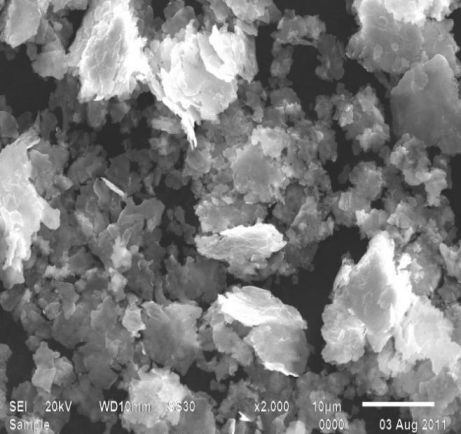

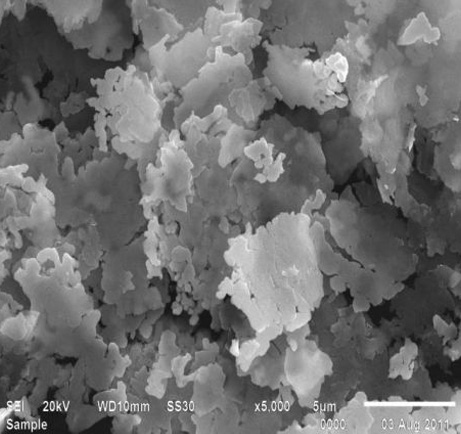

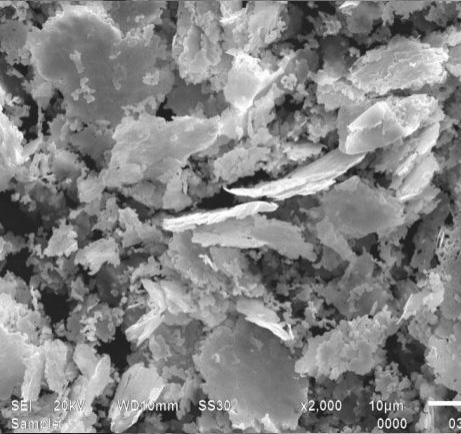

Electron microscope image |

|

|

|

|